How the FDA Ensures Generic Drug Quality During Manufacturing

- Colin Hurd

- 14 December 2025

- 9 Comments

When you pick up a generic pill at the pharmacy, you expect it to work just like the brand-name version. But how does the FDA make sure that’s true-not just in theory, but in every batch, every factory, every country? It’s not magic. It’s a strict, science-backed system built to catch problems before they reach you.

What the FDA Actually Checks

The FDA doesn’t just test the final pill. That’s outdated thinking. Instead, they focus on how the drug is made. This approach, called Current Good Manufacturing Practices (cGMP), is the backbone of every generic drug approved in the U.S. It’s not optional. It’s mandatory. And it covers every single step: from the raw chemicals arriving at the factory, to the final bottle sitting on the shelf.cGMP rules are written in Title 21 of the Code of Federal Regulations, Parts 210 and 211. They’re not suggestions. They’re legal requirements. And the FDA inspects factories-often without warning-to make sure they’re following them.

The Five Pillars of Generic Drug Quality

There are five key areas the FDA watches like a hawk:- Control of Materials: Every ingredient, even the tiniest one, must be tracked. Where did it come from? Who made it? Was it stored properly? If a batch of active ingredient is contaminated, the whole production line can be stopped. The FDA requires full documentation-no exceptions.

- Production and Process Controls: Every step in making the drug has a written procedure. Temperature, mixing time, pressure-all of it is monitored in real time. If a machine goes out of range, the system flags it. And someone has to explain why, and fix it, before moving forward.

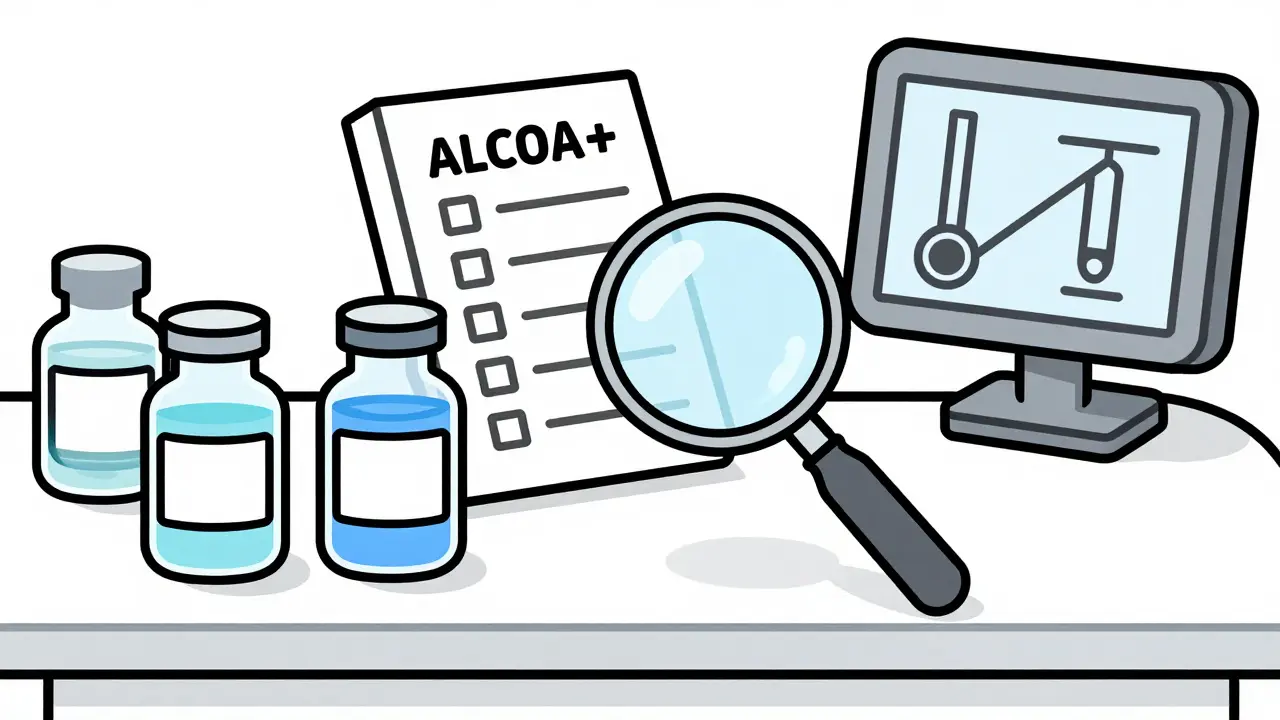

- Quality Control and Laboratory Testing: Every batch is tested. Not just the final product. Raw materials. In-process samples. Finished tablets. Tests must be validated, meaning they’re proven to work. And every result must be recorded properly-legible, dated, accurate, and traceable. That’s the ALCOA+ rule: Attributable, Legible, Contemporaneous, Original, Accurate, Complete, Consistent, Enduring, Available.

- Packaging and Labeling: A mislabeled pill can be deadly. The FDA checks that the right drug, dose, and instructions are on every label. Packaging must protect the drug from moisture, light, and contamination. Even the ink on the bottle is regulated.

- Documentation and Record Keeping: This might sound boring, but it’s the most important part. If it wasn’t written down, the FDA assumes it didn’t happen. Every shift, every test, every adjustment, every deviation-recorded. These records can be reviewed months or years later. That’s how the FDA traces problems back to their source.

How the FDA Inspects Factories

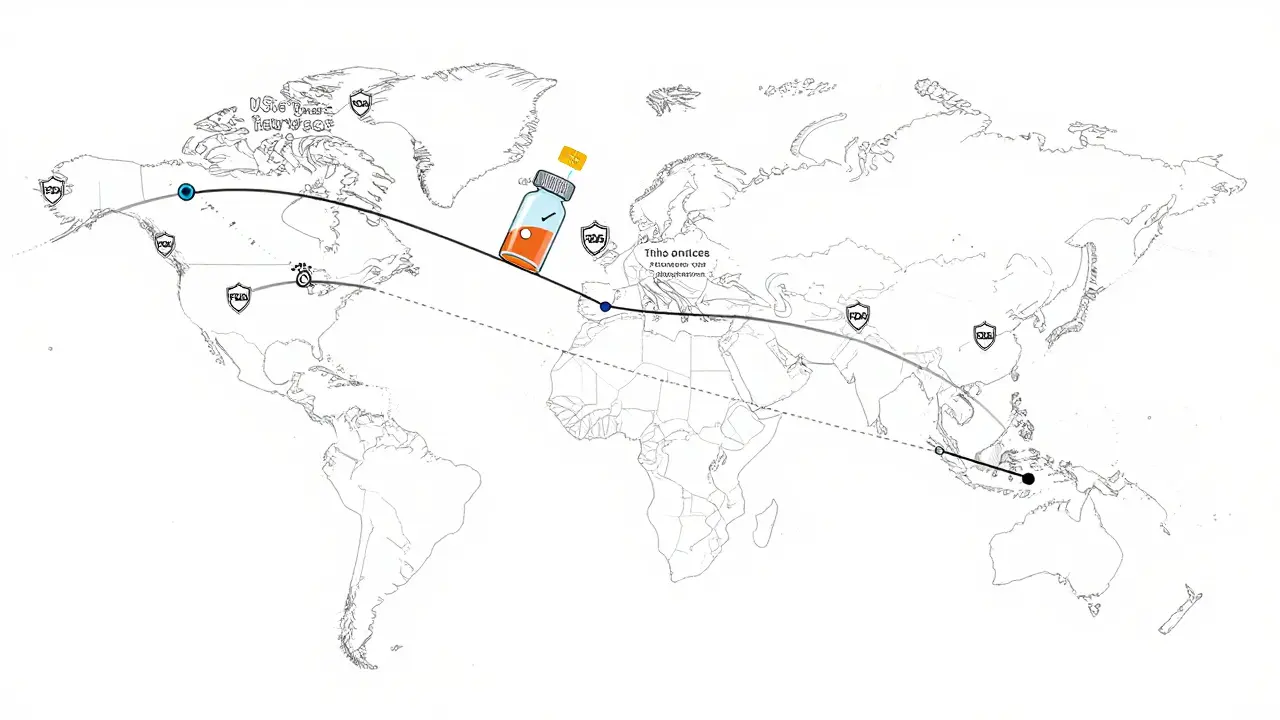

The FDA doesn’t wait for complaints. They show up unannounced. Inspectors can stay for days, even weeks, if they need to. They review records, watch operations, interview staff, and take samples. They don’t just check one batch-they look at how the system works over time.In 2023, the FDA inspected about 1,200 manufacturing sites globally. About 1,700 facilities make generic drugs for the U.S. market. Nearly half are outside the U.S., mostly in India and China. The FDA found cGMP violations at 17% of foreign sites compared to 8% of U.S. sites. That doesn’t mean foreign drugs are unsafe. It means the FDA is looking harder where the risk is higher.

Since the pandemic, the FDA has also used Remote Interactive Evaluations (RIEs). These are video tours and digital document reviews. They’re not a replacement for in-person visits, but they help prioritize which sites need a physical inspection.

What Happens Before a Generic Drug Is Approved

Before a generic drug hits the market, the manufacturer submits an Abbreviated New Drug Application (ANDA). This isn’t a quick form. It’s a thick stack of data-chemistry, manufacturing, testing, stability, bioequivalence.Here’s one detail most people don’t know: For each drug strength, the manufacturer must submit three separate batches of the active ingredient blend. One batch is used to make the main strength. The other two are used to test the lowest and highest strengths. Why? Because if the mixing process works for one dose, it doesn’t mean it works for all. This catches problems early.

The review process takes months-sometimes over a year. The FDA’s Office of Generic Drugs works hand-in-hand with the Office of Pharmaceutical Quality. One team checks the science. The other checks the factory. No shortcuts.

Why This System Works

Generic drugs make up 90% of all prescriptions filled in the U.S. That’s 6.8 billion pills a year. And they cost 80-85% less than brand-name drugs. But low cost doesn’t mean low quality. The FDA’s system ensures that.Studies show generic drugs are therapeutically equivalent to brand-name drugs in 98-99% of cases. That’s not luck. It’s because the FDA doesn’t trust the final product alone. They trust the process. If the process is solid, the product will be too.

During the pandemic, this system helped prevent shortages. When a factory had a problem making a critical antibiotic, the FDA’s Office of Manufacturing Quality stepped in quickly. They worked with the company to fix the issue-without pulling the drug off the market. That’s proactive oversight.

Challenges and Criticisms

The system isn’t perfect. Smaller manufacturers say the paperwork alone eats up 30-40% of their development time. Some say the cost of compliance-$2 to $5 million just to get started-is too high for small players.There’s also the issue of data integrity. In 2022, 42% of FDA inspection findings (Form 483s) were about bad record-keeping. Fake data. Backdated entries. Missing logs. These aren’t accidents. They’re intentional. And the FDA treats them as serious violations.

Some experts argue the FDA still relies too much on self-reported data. Manufacturers report their own test results. The FDA samples and verifies-but not every batch. That’s a gap. But the agency is moving toward more risk-based sampling. They target changes in manufacturing, new suppliers, or past violators first.

What’s Next for Generic Drug Quality

The FDA is pushing for smarter manufacturing. Their Pharmaceutical Quality for the 21st Century initiative is testing new tech:- Continuous manufacturing-making drugs in one steady flow instead of in batches.

- Real-time release testing-using sensors to check quality as the drug is made, instead of waiting for lab results.

These aren’t science fiction. They’re already being used by some top manufacturers. The FDA expects to issue draft guidance in 2024.

Also, starting in 2025, companies will have to report where their active ingredients come from-down to the specific supplier. That’s a big step toward supply chain transparency.

The Generic Drug User Fee Amendments (GDUFA) III, which started in 2022, gave the FDA $650 million over five years to hire more inspectors, improve tech, and speed up reviews. That money is already making a difference.

Bottom Line

You don’t need to worry that your generic pill is weak or fake. The FDA’s system is designed to catch that before it ever leaves the factory. It’s not perfect, but it’s the most thorough in the world. And it’s why you can trust a $5 generic as much as a $50 brand-name drug.Quality isn’t something you test at the end. It’s built in-from the first gram of powder to the last pill in the bottle.

Are generic drugs as effective as brand-name drugs?

Yes. The FDA requires generic drugs to be bioequivalent to their brand-name counterparts, meaning they deliver the same amount of active ingredient into the bloodstream at the same rate. Studies show they work the same in 98-99% of cases. The only differences are in inactive ingredients like color or flavor-things that don’t affect how the drug works.

Does the FDA inspect foreign drug factories?

Yes. Nearly half of the facilities making generic drugs for the U.S. are overseas, mostly in India and China. The FDA inspects them just like U.S. plants-often unannounced. In 2023, the agency conducted over 1,200 inspections globally. Foreign facilities had higher rates of violations, but that’s why they’re inspected more often.

How long does it take to get a generic drug approved?

It typically takes 12 to 24 months from submission to approval. The process includes multiple review cycles. Each cycle can take several months. The FDA reviews chemistry, manufacturing, testing, and bioequivalence data. The time varies depending on how complete the application is and whether the FDA has questions.

What happens if a generic drug fails an FDA inspection?

If serious violations are found, the FDA can issue a warning letter. The company must fix the issues and prove they’re fixed. If they don’t, the FDA can block the drug from entering the U.S. market. In extreme cases, the facility may be barred from making drugs for Americans. The FDA doesn’t shut down factories lightly-but they will if safety is at risk.

Can I trust a generic drug made overseas?

Yes-if it’s approved by the FDA. The agency holds all manufacturers, whether in the U.S., India, or China, to the same standards. A generic drug sold in the U.S. must meet the same quality, safety, and effectiveness rules, no matter where it’s made. The FDA inspects foreign facilities just as rigorously as U.S. ones.

Why do generic drugs cost so much less?

Generic manufacturers don’t have to repeat expensive clinical trials because they’re proving equivalence, not safety from scratch. Their biggest costs are in manufacturing and FDA compliance-not research. That’s why they can sell the same drug for 80-85% less. The savings go to patients and the healthcare system.

Comments

Harriet Wollaston

Just had to say this-my grandma takes six generics a day and still hikes every morning. I used to worry, but now I get it. This system? It’s why she’s still here. Thanks for explaining it so clearly.

Love that the FDA doesn’t just take their word for it. Real people’s lives are on the line, not just profit margins.

December 15, 2025 AT 07:20

Lauren Scrima

So… let me get this straight: you’re telling me that the same FDA that lets airlines get away with broken seatbelts is the one policing pill factories with military precision? 😏

December 16, 2025 AT 04:45

sharon soila

Quality is not an accident. It is a choice. Every time a worker writes down a number, every time a machine is calibrated, every time a supervisor says ‘stop’-that is a choice to care.

This is not just science. This is morality made visible. We should be proud that our country demands this level of integrity-even for a $5 pill.

It is not about cost. It is about character.

December 17, 2025 AT 12:27

nina nakamura

17% violation rate in India? That’s not a bug, it’s a feature of the system. The FDA lets this happen because they’re too lazy to shut it down. You think they care about your grandma? They care about lawsuits. And they know you’ll still buy the pill anyway.

Self-reported data? That’s not oversight, it’s a joke. They sample 1 in 1000 batches and call it a day. Wake up.

December 19, 2025 AT 05:09

Alvin Montanez

Let me tell you something about this whole generic drug thing. The FDA doesn’t have enough inspectors to cover even 10% of the plants they’re supposed to be watching. The whole system is built on trust and paper trails and if you think that’s enough to keep you safe, you’re either naive or you’ve never worked in manufacturing. I’ve seen the inside of these factories. They’re not labs. They’re assembly lines with a clipboard and a prayer. And when the pressure’s on to meet quotas? The logs get ‘adjusted.’ You think the FDA catches every backdated entry? Nah. They catch the ones that are sloppy. The smart ones? They’re still shipping. And you’re still swallowing.

Don’t believe the PR. This isn’t safety. It’s damage control with a badge.

December 20, 2025 AT 04:23

Lara Tobin

Thank you for sharing this 😊 I had no idea so much went into it. I always thought generics were just cheaper copies, but now I see they’re like the quiet heroes of medicine. 🙏

December 22, 2025 AT 03:11

Jamie Clark

You people act like this is some miracle system. It’s not. It’s bureaucratic theater. The FDA is a glorified paper-pusher with a badge. They inspect a factory once every three years and call it ‘risk-based.’ Meanwhile, people are dying from contaminated valsartan and metformin because the agency was too busy chasing ‘efficiency’ to actually enforce. The system is broken because it’s designed to protect corporations, not patients. Stop pretending this is safety. It’s compliance theater with a FDA logo on it.

December 23, 2025 AT 13:07

Keasha Trawick

Okay, so picture this: a factory in Hyderabad, 3 a.m., humid as hell, machines humming like a choir of angry bees. A technician drops a vial of API-active pharmaceutical ingredient, baby-and instead of scrapping it? They ‘reprocess’ it. No one sees it. No one logs it. But the spectrometer? It doesn’t lie. The FDA’s new real-time sensors? They’ll catch the molecular fingerprint of that shortcut before it even hits the tablet press. This isn’t just quality control-it’s pharmaceutical forensics on steroids. And the best part? The next batch? It’s gonna be flawless. Because the system doesn’t just react-it evolves. We’re not just making pills anymore. We’re engineering trust, one microgram at a time. 🔬💥

December 24, 2025 AT 07:56

Webster Bull

Fact: the FDA doesn't need to check every pill. They check the system. And if the system works? The pill works. Simple. Smart. And yeah, it's why my blood pressure med costs $4 and not $400. 👍

December 25, 2025 AT 22:47